-

Features

Body Material Cum Standard

Cast Iron (IBR 86 to 93 Gr. A)

Product Description

Pilot Operated, Outlet Pressure Range available 5/45, 40/100, 90/125 Psig

Type of Seat

Renewable Seat

Trim

13% Cr. (SS 410) + Stellited Facing

End Details

Flanged Ends as per BS-10 Table-F Flat Face (Undrilled)

Test Pressure

Body: 300 Psig (Hyd.)

Max. Working Pressure

150 Psig (Steam)

Max. Working Temperature

220°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

-

Material Combination

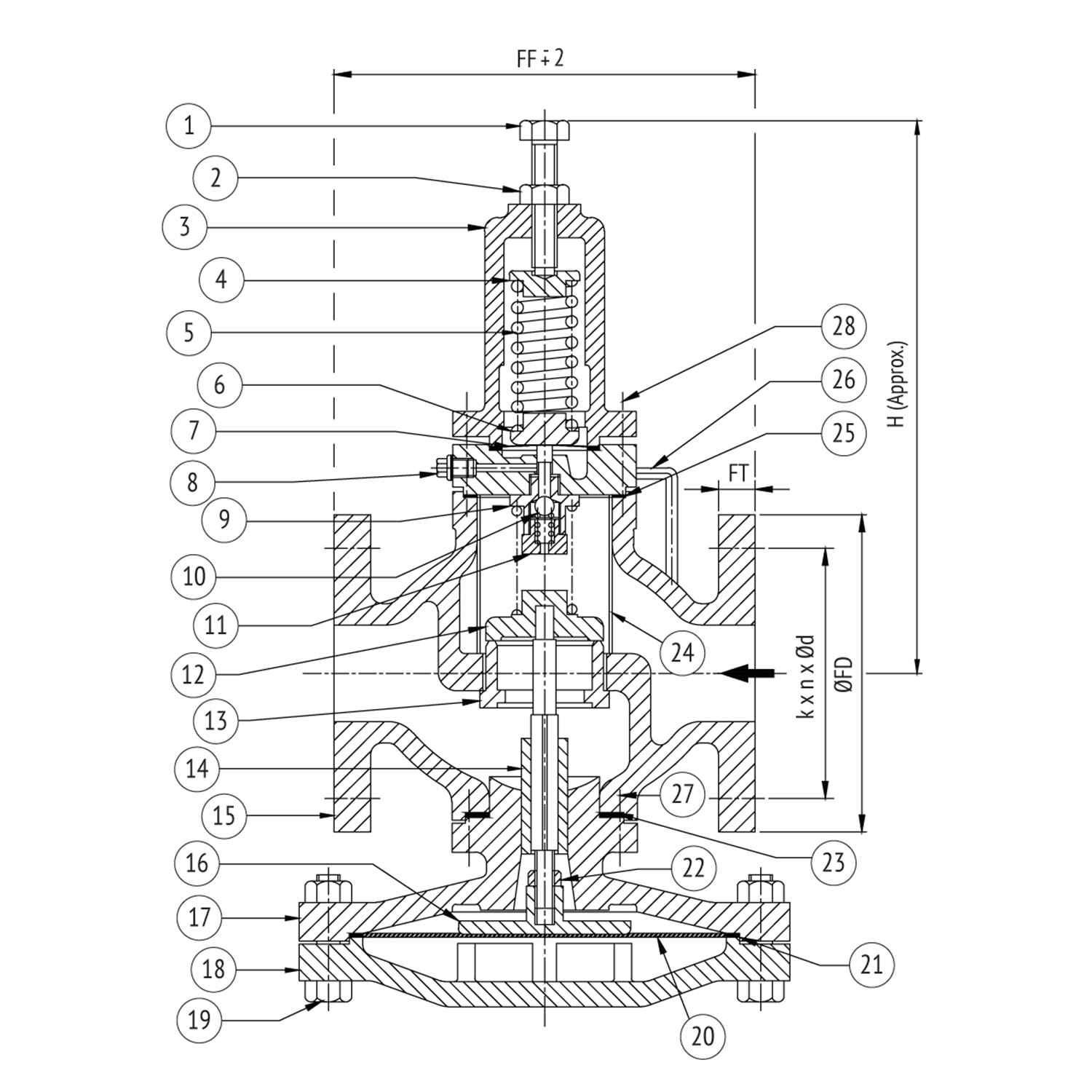

S.No Description No. Material Specifications 1,2 Adjusting Screw, Locking Nut 1 Carbon Steel – 3 Spring Housing 1 S.G.I. EN 1563 Gr. GJS-400-15 4, 6 Spring Top Disc, Spring Bottom Disc 1 Stainless Steel AISI 410 5, 7 Pressure Adjusting Spring, Diaphragm 1 Stainless Steel AISI 304 8 Side Plug 1 Stainless Steel AISI 410 9, 10 Pilot Valve Body, Ball 1 Stainless Steel AISI 304 11 Pilot Valve Spring Retaining Check Nut 1 Stainless Steel AISI 304 12, 13 Main Valve Disc, Body Seat Ring 1 Stainless Steel AISI 410 + Stellite 14 Push Rod Guide Sleeve 1 Stainless Steel AISI 410 15 Main Valve Body 1 Cast Iron IBR 86 to 93 Gr.A 16 Main Diaphragm Disc 1 G.M. / S.S. IBR 282 (a) (iv) Gr. B / AISI 410 17, 18 Half Upper Cover, Half Lower Cover 1 Cast Iron IBR 86 to 93 Gr.A 19 Bolts & Nuts To Suit Carbon Steel – 20 Diaphragm 1 Stainless Steel AISI 304 21, 23 Gasket 1 C.A.F. IS 2712 22 Push Rod Lock Nut 1 Stainless Steel AISI 410 24 Strainer Screen 1 Stainless Steel AISI 304 25 Gasket 1 C.A.F. – 26 By Pass Assy. – – – 27, 28 Studs & Nuts To Suit Carbon Steel – -

Dimensional Data

Size (mm) FF H ØFD FT k n Ød 25 165 215 120.7 12.7 87.3 4 17.5 40 203 245 139.7 15.9 104.8 4 17.5 50 248 295 165.1 19.1 127 4 17.5

Features

Body Material Cum Standard

Cast Iron (IBR 86 to 93 Gr. A)

Product Description

Pilot Operated, Outlet Pressure Range available 5/45, 40/100, 90/125 Psig

Type of Seat

Renewable Seat

Trim

13% Cr. (SS 410) + Stellited Facing

End Details

Flanged Ends as per BS-10 Table-F Flat Face (Undrilled)

Test Pressure

Body: 300 Psig (Hyd.)

Max. Working Pressure

150 Psig (Steam)

Max. Working Temperature

220°C

Body Material Cum Standard

Cast Iron (IBR 86 to 93 Gr. A)

Product Description

Pilot Operated, Outlet Pressure Range available 5/45, 40/100, 90/125 Psig

Type of Seat

Renewable Seat

Trim

13% Cr. (SS 410) + Stellited Facing

End Details

Flanged Ends as per BS-10 Table-F Flat Face (Undrilled)

Test Pressure

Body: 300 Psig (Hyd.)

Max. Working Pressure

150 Psig (Steam)

Max. Working Temperature

220°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

S.No

Description

No.

Material

Specifications

1,2

Adjusting Screw, Locking Nut

1

Carbon Steel

–

3

Spring Housing

1

S.G.I.

EN 1563 Gr. GJS-400-15

4, 6

Spring Top Disc, Spring Bottom Disc

1

Stainless Steel

AISI 410

5, 7

Pressure Adjusting Spring, Diaphragm

1

Stainless Steel

AISI 304

8

Side Plug

1

Stainless Steel

AISI 410

9, 10

Pilot Valve Body, Ball

1

Stainless Steel

AISI 304

11

Pilot Valve Spring Retaining Check Nut

1

Stainless Steel

AISI 304

12, 13

Main Valve Disc, Body Seat Ring

1

Stainless Steel

AISI 410 + Stellite

14

Push Rod Guide Sleeve

1

Stainless Steel

AISI 410

15

Main Valve Body

1

Cast Iron

IBR 86 to 93 Gr.A

16

Main Diaphragm Disc

1

G.M. / S.S.

IBR 282 (a) (iv) Gr. B / AISI 410

17, 18

Half Upper Cover, Half Lower Cover

1

Cast Iron

IBR 86 to 93 Gr.A

19

Bolts & Nuts

To Suit

Carbon Steel

–

20

Diaphragm

1

Stainless Steel

AISI 304

21, 23

Gasket

1

C.A.F.

IS 2712

22

Push Rod Lock Nut

1

Stainless Steel

AISI 410

24

Strainer Screen

1

Stainless Steel

AISI 304

25

Gasket

1

C.A.F.

–

26

By Pass Assy.

–

–

–

27, 28

Studs & Nuts

To Suit

Carbon Steel

–

| S.No | Description | No. | Material | Specifications |

|---|---|---|---|---|

| 1,2 | Adjusting Screw, Locking Nut | 1 | Carbon Steel | – |

| 3 | Spring Housing | 1 | S.G.I. | EN 1563 Gr. GJS-400-15 |

| 4, 6 | Spring Top Disc, Spring Bottom Disc | 1 | Stainless Steel | AISI 410 |

| 5, 7 | Pressure Adjusting Spring, Diaphragm | 1 | Stainless Steel | AISI 304 |

| 8 | Side Plug | 1 | Stainless Steel | AISI 410 |

| 9, 10 | Pilot Valve Body, Ball | 1 | Stainless Steel | AISI 304 |

| 11 | Pilot Valve Spring Retaining Check Nut | 1 | Stainless Steel | AISI 304 |

| 12, 13 | Main Valve Disc, Body Seat Ring | 1 | Stainless Steel | AISI 410 + Stellite |

| 14 | Push Rod Guide Sleeve | 1 | Stainless Steel | AISI 410 |

| 15 | Main Valve Body | 1 | Cast Iron | IBR 86 to 93 Gr.A |

| 16 | Main Diaphragm Disc | 1 | G.M. / S.S. | IBR 282 (a) (iv) Gr. B / AISI 410 |

| 17, 18 | Half Upper Cover, Half Lower Cover | 1 | Cast Iron | IBR 86 to 93 Gr.A |

| 19 | Bolts & Nuts | To Suit | Carbon Steel | – |

| 20 | Diaphragm | 1 | Stainless Steel | AISI 304 |

| 21, 23 | Gasket | 1 | C.A.F. | IS 2712 |

| 22 | Push Rod Lock Nut | 1 | Stainless Steel | AISI 410 |

| 24 | Strainer Screen | 1 | Stainless Steel | AISI 304 |

| 25 | Gasket | 1 | C.A.F. | – |

| 26 | By Pass Assy. | – | – | – |

| 27, 28 | Studs & Nuts | To Suit | Carbon Steel | – |

Dimensional Data

Size (mm)

FF

H

ØFD

FT

k

n

Ød

25

165

215

120.7

12.7

87.3

4

17.5

40

203

245

139.7

15.9

104.8

4

17.5

50

248

295

165.1

19.1

127

4

17.5

| Size (mm) | FF | H | ØFD | FT | k | n | Ød |

|---|---|---|---|---|---|---|---|

| 25 | 165 | 215 | 120.7 | 12.7 | 87.3 | 4 | 17.5 |

| 40 | 203 | 245 | 139.7 | 15.9 | 104.8 | 4 | 17.5 |

| 50 | 248 | 295 | 165.1 | 19.1 | 127 | 4 | 17.5 |

All Rights Reserved. Atam Valves Limited