-

Features

Product Standard

BS-1868

Testing Standard

API-598

Pressure / Class Rating

Class-600

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Bolted Cover

Type of Seat

Renewable Seat

Trim

13% Cr. (SS 410)

End Details

Flanged Ends as per ASME B16.5 Class-600 Raised Face (Drilled)

Test Pressure

Body: 153 Bar (Hyd.), Seat: 112 Bar (Hyd.), Seat: 7 Bar (Air)

Max. Working Temperature

425°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Other trim material combinations are available on request.

Suitability

Water

Steam

Gas

Oil

Air

-

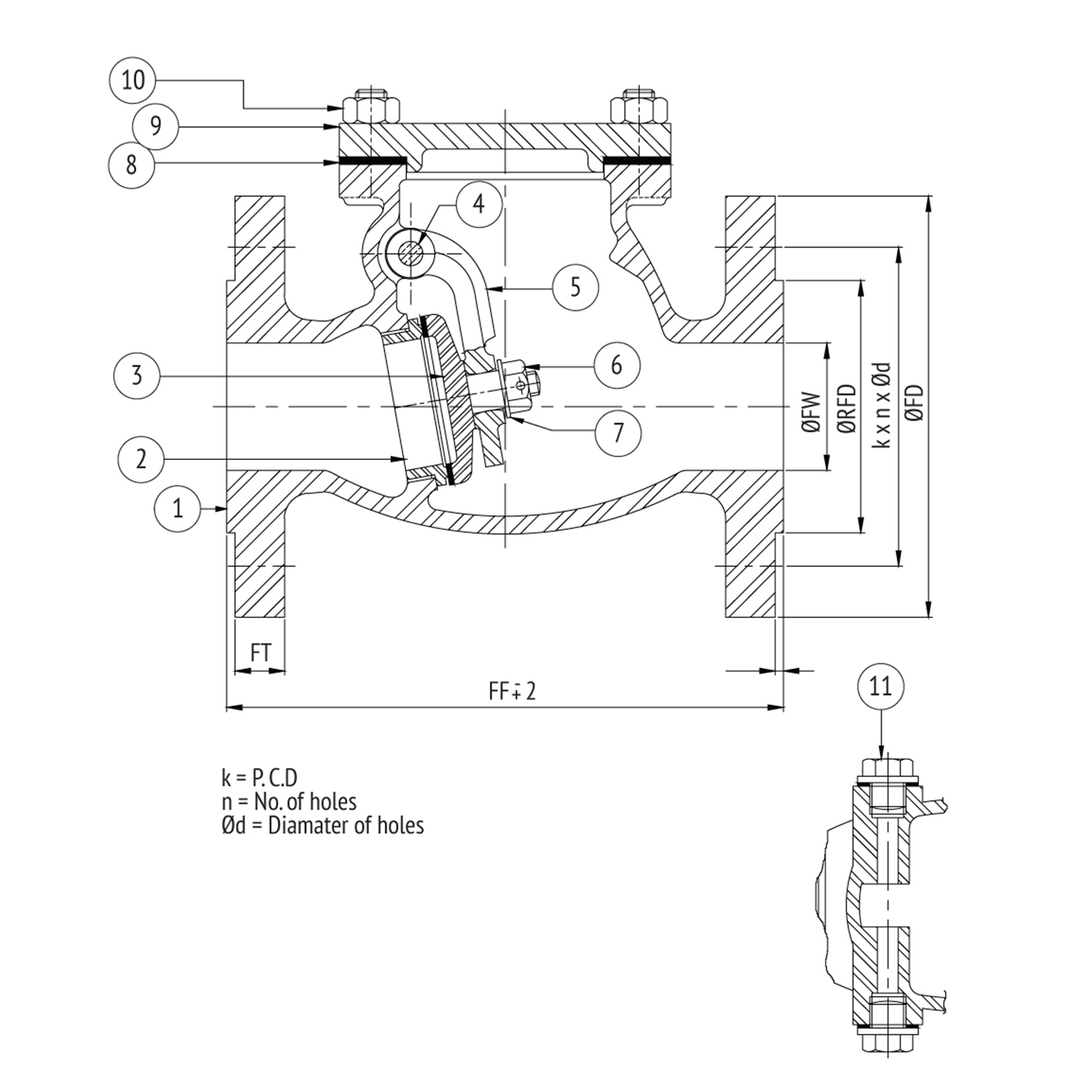

Material Combination

P.No. Name of Part Material Specification Nos. 1 Body C.C.S ASTM A216 Gr. WCB 1 2 Body Seat Ring S.S./ F.S.S./ C.C.S. ASTM A276 TYPE 410/ ASTM A182 Gr. F6a/ ASTM A216 Gr. WCB + 13% Cr. Deposit 2 3 Disc C.C.S. ASTM A216 Gr. WCB + 13% Cr. Deposit 1 4 Hinge Pin S.S. ASTM A276 TYPE 410 1 5 Hinge C.C.S. ASTM A216 Gr. WCB 1 6 Nut S.S. – 1 7 Washer Carbon Steel – To Suit 8 Gasket Spiral Wound S.S. 304 with Graphite Filler Inner Ring – 1 9 Cover C.C.S. ASTM A216 Gr. WCB 1 10 Stud & Nuts Alloy Steel/ H.T. Steel ASTM A193 Gr. B7/ ASTM A194 Gr. 2H 1 10 Side Plug S.S. ASTM A276 TYPE 410 1 -

Dimensional Data

Nominal Size (mm) FF ØFW ØFD ØRFD FT k n Ød 40 241 38 155 73 22.3 114.3 4 7/8″ 50 292 51 165 92.1 25.4 127 8 3/4″ 65 330 64 190 104.8 28.6 149.2 8 7/8″ 80 356 76 210 127 31.8 168.3 8 7/8″ 100 432 102 275 157.2 38.1 215.9 8 1″ 125 508 127 330 185.7 44.5 266.7 8 1.1/8″ 150 559 152 355 215.9 47.7 292.1 12 1.1/8″ 200 660 200 420 269.9 55.6 349.2 12 1.1/4″ 250 787 248 510 323.8 63.5 431.8 16 1.3/8″ k – P.C.D; n – Number of Holes; Ød – Diameter of Holes

Features

Product Standard

BS-1868

Testing Standard

API-598

Pressure / Class Rating

Class-600

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Bolted Cover

Type of Seat

Renewable Seat

Trim

13% Cr. (SS 410)

End Details

Flanged Ends as per ASME B16.5 Class-600 Raised Face (Drilled)

Test Pressure

Body: 153 Bar (Hyd.), Seat: 112 Bar (Hyd.), Seat: 7 Bar (Air)

Max. Working Temperature

425°C

Product Standard

BS-1868

Testing Standard

API-598

Pressure / Class Rating

Class-600

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Bolted Cover

Type of Seat

Renewable Seat

Trim

13% Cr. (SS 410)

End Details

Flanged Ends as per ASME B16.5 Class-600 Raised Face (Drilled)

Test Pressure

Body: 153 Bar (Hyd.), Seat: 112 Bar (Hyd.), Seat: 7 Bar (Air)

Max. Working Temperature

425°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Other trim material combinations are available on request.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

P.No.

Name of Part

Material

Specification

Nos.

1

Body

C.C.S

ASTM A216 Gr. WCB

1

2

Body Seat Ring

S.S./ F.S.S./ C.C.S.

ASTM A276 TYPE 410/ ASTM A182 Gr. F6a/ ASTM A216 Gr. WCB + 13% Cr. Deposit

2

3

Disc

C.C.S.

ASTM A216 Gr. WCB + 13% Cr. Deposit

1

4

Hinge Pin

S.S.

ASTM A276 TYPE 410

1

5

Hinge

C.C.S.

ASTM A216 Gr. WCB

1

6

Nut

S.S.

–

1

7

Washer

Carbon Steel

–

To Suit

8

Gasket

Spiral Wound S.S. 304 with Graphite Filler Inner Ring

–

1

9

Cover

C.C.S.

ASTM A216 Gr. WCB

1

10

Stud & Nuts

Alloy Steel/ H.T. Steel

ASTM A193 Gr. B7/ ASTM A194 Gr. 2H

1

10

Side Plug

S.S.

ASTM A276 TYPE 410

1

| P.No. | Name of Part | Material | Specification | Nos. |

|---|---|---|---|---|

| 1 | Body | C.C.S | ASTM A216 Gr. WCB | 1 |

| 2 | Body Seat Ring | S.S./ F.S.S./ C.C.S. | ASTM A276 TYPE 410/ ASTM A182 Gr. F6a/ ASTM A216 Gr. WCB + 13% Cr. Deposit | 2 |

| 3 | Disc | C.C.S. | ASTM A216 Gr. WCB + 13% Cr. Deposit | 1 |

| 4 | Hinge Pin | S.S. | ASTM A276 TYPE 410 | 1 |

| 5 | Hinge | C.C.S. | ASTM A216 Gr. WCB | 1 |

| 6 | Nut | S.S. | – | 1 |

| 7 | Washer | Carbon Steel | – | To Suit |

| 8 | Gasket | Spiral Wound S.S. 304 with Graphite Filler Inner Ring | – | 1 |

| 9 | Cover | C.C.S. | ASTM A216 Gr. WCB | 1 |

| 10 | Stud & Nuts | Alloy Steel/ H.T. Steel | ASTM A193 Gr. B7/ ASTM A194 Gr. 2H | 1 |

| 10 | Side Plug | S.S. | ASTM A276 TYPE 410 | 1 |

Dimensional Data

Nominal Size (mm)

FF

ØFW

ØFD

ØRFD

FT

k

n

Ød

40

241

38

155

73

22.3

114.3

4

7/8″

50

292

51

165

92.1

25.4

127

8

3/4″

65

330

64

190

104.8

28.6

149.2

8

7/8″

80

356

76

210

127

31.8

168.3

8

7/8″

100

432

102

275

157.2

38.1

215.9

8

1″

125

508

127

330

185.7

44.5

266.7

8

1.1/8″

150

559

152

355

215.9

47.7

292.1

12

1.1/8″

200

660

200

420

269.9

55.6

349.2

12

1.1/4″

250

787

248

510

323.8

63.5

431.8

16

1.3/8″

k – P.C.D; n – Number of Holes; Ød – Diameter of Holes

| Nominal Size (mm) | FF | ØFW | ØFD | ØRFD | FT | k | n | Ød |

|---|---|---|---|---|---|---|---|---|

| 40 | 241 | 38 | 155 | 73 | 22.3 | 114.3 | 4 | 7/8″ |

| 50 | 292 | 51 | 165 | 92.1 | 25.4 | 127 | 8 | 3/4″ |

| 65 | 330 | 64 | 190 | 104.8 | 28.6 | 149.2 | 8 | 7/8″ |

| 80 | 356 | 76 | 210 | 127 | 31.8 | 168.3 | 8 | 7/8″ |

| 100 | 432 | 102 | 275 | 157.2 | 38.1 | 215.9 | 8 | 1″ |

| 125 | 508 | 127 | 330 | 185.7 | 44.5 | 266.7 | 8 | 1.1/8″ |

| 150 | 559 | 152 | 355 | 215.9 | 47.7 | 292.1 | 12 | 1.1/8″ |

| 200 | 660 | 200 | 420 | 269.9 | 55.6 | 349.2 | 12 | 1.1/4″ |

| 250 | 787 | 248 | 510 | 323.8 | 63.5 | 431.8 | 16 | 1.3/8″ |

k – P.C.D; n – Number of Holes; Ød – Diameter of Holes

Products (By Valve Type)

Check Valves

All Rights Reserved. Atam Valves Limited