-

Features

Body Material Cum Standard

Cast Stainless Steel (ASTM A351 Gr. CF8) (SS 304)

Product Description

Compact Size, Diaphragm Type

End Details

Screwed Female BSP Parallel Threads (BS-21)

Test Pressure

Body : 24 kg/cm² (Hyd.)

Max. Working Pressure

Max. Inlet Pressure : 16 kg/cm², Outlet Pressure Range : 1.5 – 5 kg/cm²

Max. Working Temperature

45°C

· Diaphragm Type · With in-built screen mesh to prevent dirt particles from entering internal parts, with easy attachment no need to remove the valve from pipeline for cleaning screen. · With transparent bottom cap, dirt particles can be easily seen. · In-built provision of installation of pressure gauge. · Easy to operate and adjust. · Constant set outlet pressure, irrespective of inlet pressure fluctuations in the line.

Suitability

Water

Steam

Gas

Oil

Air

-

Material Combination

S.No Description No. Material Specifications 1 Bottom Cap 1 Thermo Plastic Transparent 2 Body 1 C.S.S. ASTM A351 Gr. CF8 (SS 304) 3 Bonnet 1 Nylon 6 Based – 4 Adjusting Screw 1 Stainless Steel AISI 304 5 Plug 1 Nylon 6 Based – Internal Components :

Diaphragm & Seals – Nitrile

Internal Valve Disc Cartridge – High Quality Engineered Plastic

Filter Screen Mesh & Spring – S.S. (AISI 304) -

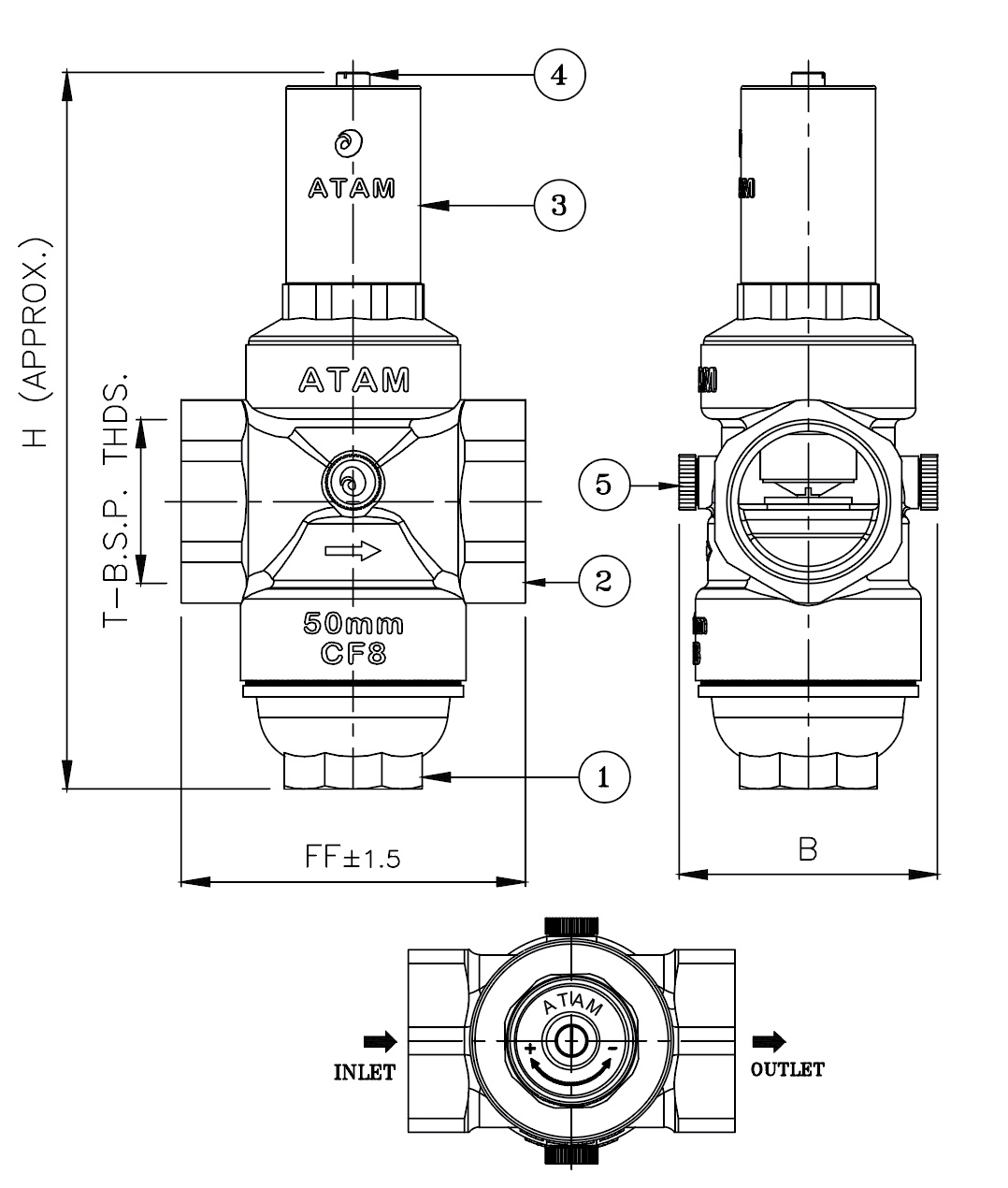

Dimensional Data

Size (mm) Size (inches) FF H B 15 1/2″ 74 140 77 20 3/4″ 78 140 77 25 1″ 98 170 86 32 1.1/4″ 102 170 86 40 1.1/2″ 120 260 94 50 2″ 125 260 94

Features

Body Material Cum Standard

Cast Stainless Steel (ASTM A351 Gr. CF8) (SS 304)

Product Description

Compact Size, Diaphragm Type

End Details

Screwed Female BSP Parallel Threads (BS-21)

Test Pressure

Body : 24 kg/cm² (Hyd.)

Max. Working Pressure

Max. Inlet Pressure : 16 kg/cm², Outlet Pressure Range : 1.5 – 5 kg/cm²

Max. Working Temperature

45°C

Body Material Cum Standard

Cast Stainless Steel (ASTM A351 Gr. CF8) (SS 304)

Product Description

Compact Size, Diaphragm Type

End Details

Screwed Female BSP Parallel Threads (BS-21)

Test Pressure

Body : 24 kg/cm² (Hyd.)

Max. Working Pressure

Max. Inlet Pressure : 16 kg/cm², Outlet Pressure Range : 1.5 – 5 kg/cm²

Max. Working Temperature

45°C

· Diaphragm Type · With in-built screen mesh to prevent dirt particles from entering internal parts, with easy attachment no need to remove the valve from pipeline for cleaning screen. · With transparent bottom cap, dirt particles can be easily seen. · In-built provision of installation of pressure gauge. · Easy to operate and adjust. · Constant set outlet pressure, irrespective of inlet pressure fluctuations in the line.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

S.No

Description

No.

Material

Specifications

1

Bottom Cap

1

Thermo Plastic

Transparent

2

Body

1

C.S.S.

ASTM A351 Gr. CF8 (SS 304)

3

Bonnet

1

Nylon 6 Based

–

4

Adjusting Screw

1

Stainless Steel

AISI 304

5

Plug

1

Nylon 6 Based

–

Internal Components :

Diaphragm & Seals – Nitrile

Internal Valve Disc Cartridge – High Quality Engineered Plastic

Filter Screen Mesh & Spring – S.S. (AISI 304)

| S.No | Description | No. | Material | Specifications | |

|---|---|---|---|---|---|

| 1 | Bottom Cap | 1 | Thermo Plastic | Transparent | |

| 2 | Body | 1 | C.S.S. | ASTM A351 Gr. CF8 (SS 304) | |

| 3 | Bonnet | 1 | Nylon 6 Based | – | |

| 4 | Adjusting Screw | 1 | Stainless Steel | AISI 304 | |

| 5 | Plug | 1 | Nylon 6 Based | – |

Internal Components :

Diaphragm & Seals – Nitrile

Internal Valve Disc Cartridge – High Quality Engineered Plastic

Filter Screen Mesh & Spring – S.S. (AISI 304)

Dimensional Data

Size (mm)

Size (inches)

FF

H

B

15

1/2″

74

140

77

20

3/4″

78

140

77

25

1″

98

170

86

32

1.1/4″

102

170

86

40

1.1/2″

120

260

94

50

2″

125

260

94

| Size (mm) | Size (inches) | FF | H | B |

|---|---|---|---|---|

| 15 | 1/2″ | 74 | 140 | 77 |

| 20 | 3/4″ | 78 | 140 | 77 |

| 25 | 1″ | 98 | 170 | 86 |

| 32 | 1.1/4″ | 102 | 170 | 86 |

| 40 | 1.1/2″ | 120 | 260 | 94 |

| 50 | 2″ | 125 | 260 | 94 |

Products (By Material)

Stainless Steel

All Rights Reserved. Atam Valves Limited